LOOKING FOR SUPPORT? CONTACT OUR POWER EXPERTS

The "press-fit" technique offers cost-effective, high-power solutions and compact designs for power circuits, catering to end customers' needs. SiCPAK does not contain any lead. Instead of using soldering, each SiC chip is joined to the module's substrate by a process called silver (Ag) sintering. This method not only ensures improved cooling but also enhances the reliability of the module. The substrate is fabricated by employing an active-metal brazing (AMB) process on silicon-nitride (Si3N4) ceramics, resulting in direct-bonded copper (DBC). This approach is optimal for power-cycling applications. Advanced construction processes provide exceptional strength and flexibility, resistance to fractures, and high heat conductivity, ensuring reliable and long-lasting performance.

onsemi EliteSiC Direct Cooling Eliminates Need for Thermal Interface Layer or Heatsink

onsemi provides innovative direct cooling methods as part of its packaging alternatives. These technologies enhance thermal conductivity, resulting in improved system performance and reliability. Integrating full SiC MOSFETs, onsemi’s EliteSiC power modules provide a direct cooling path between the coolant and the SiC chip without requiring additional thermal components like TIM or heatsinks.

SiC Packaging Technologies Increase Performance and Reliability in EV Power Systems

Traditional silicon (Si) electronics are disadvantaged in high-power applications like electric vehicle (EV) drivetrains, onboard chargers (OBCs), and EV DC fast charging stations due to limitations in switching speed and heat dissipation.

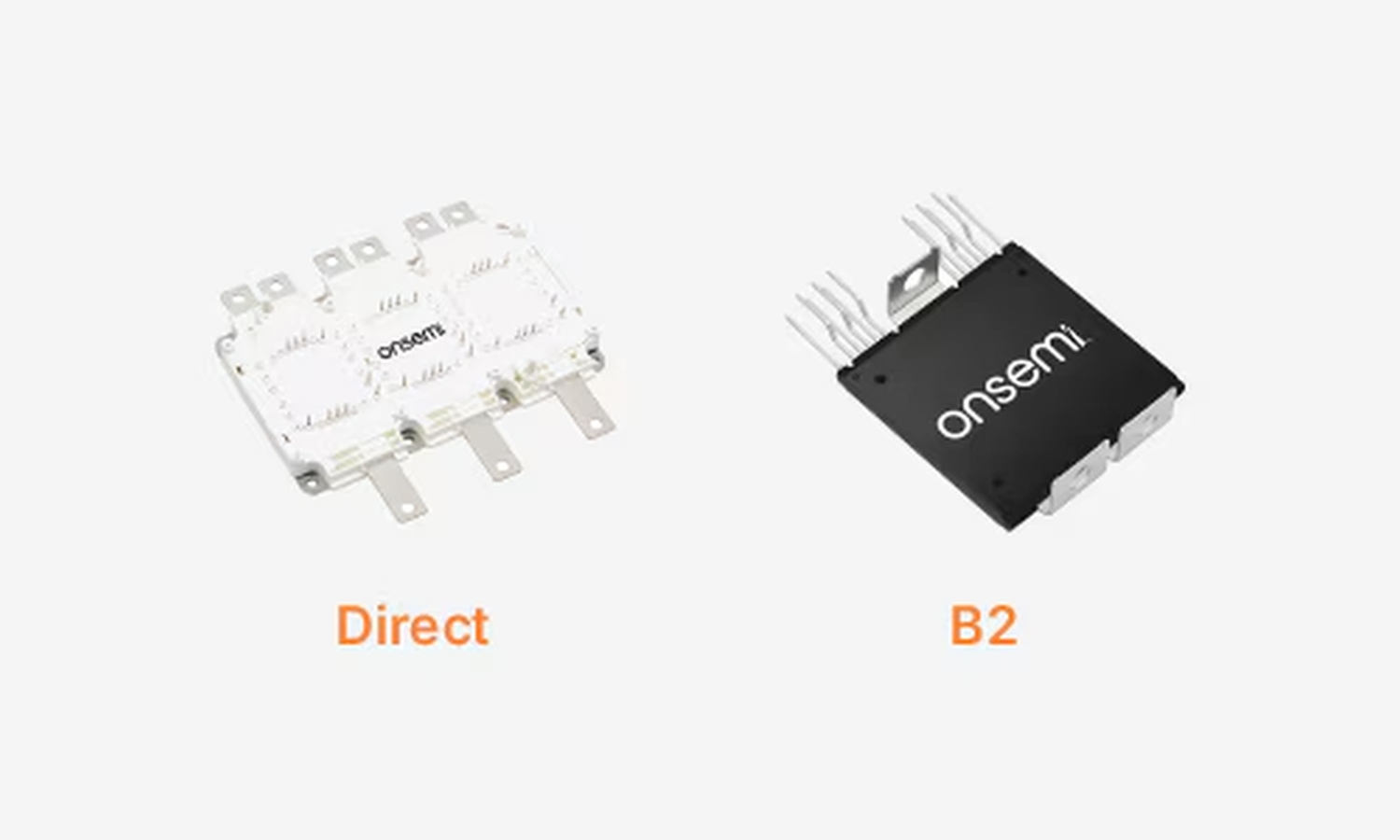

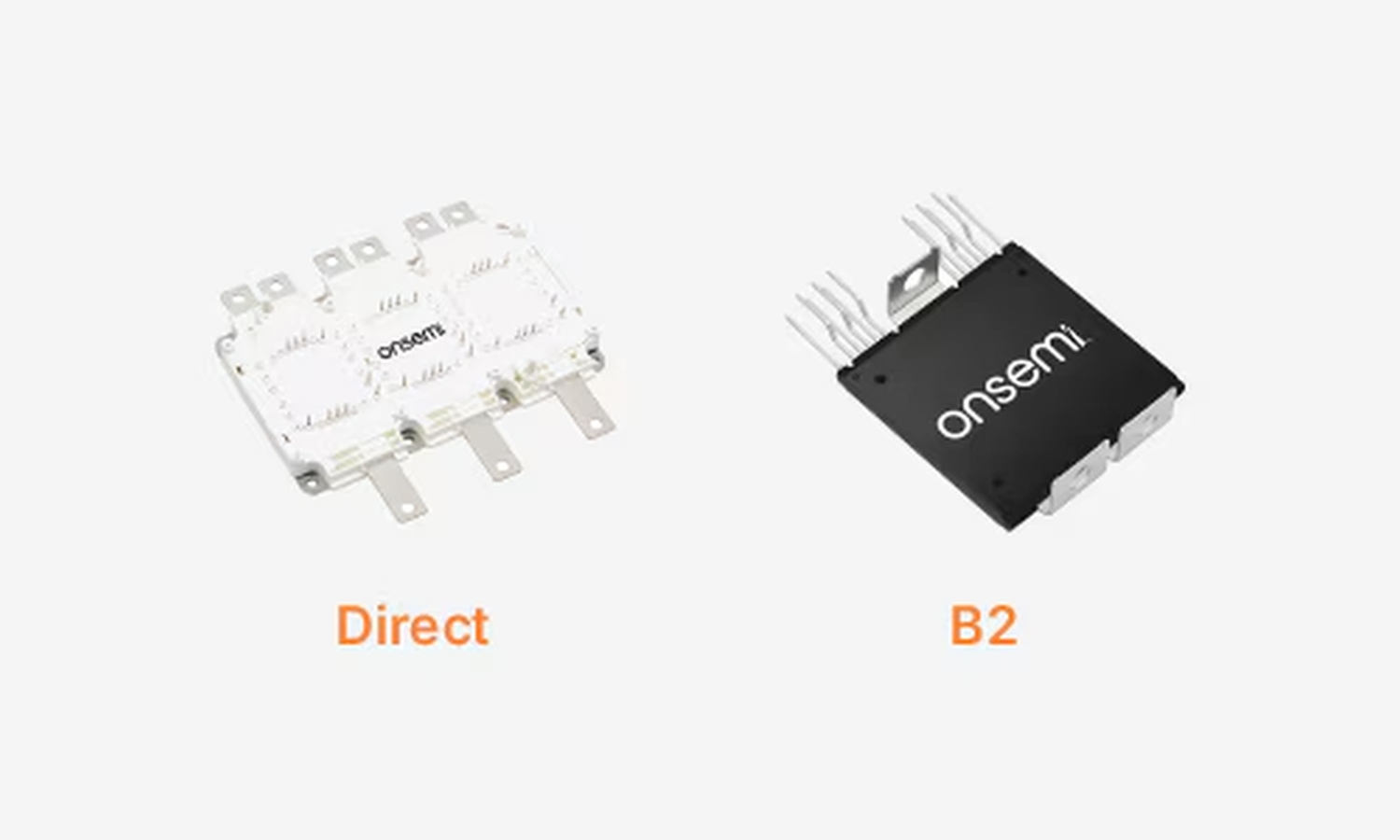

Figure 3: onsemi’s Direct and B2 SiC package options (Source: onsemi)

Silicon Carbide (SiC) offers a superior alternative, but its packaging requires a careful design. The innovative SiC packaging mentioned is changing the game for Original Equipment Manufacturers (OEMs) designing EV power systems.

These innovative SiC packaging technologies offer a range of benefits, including:

-

Higher performance: Improved thermal management and reduced electrical resistance translate to higher power densities and switching frequencies. This allows for smaller, lighter, and more efficient power electronics for the EV drivetrain.

In summary, advancements in SiC packaging technology are transforming power electronics through improved thermal management. Innovations from manufacturers like STMicroelectronics, Navitas Semiconductor, and onsemi enable SiC semiconductors to achieve durability, energy efficiency and reliability, driving progress in high-power industries such as automotive.

For more information about SiC power semiconductors, talk to the Avnet Silica Power Specialists.